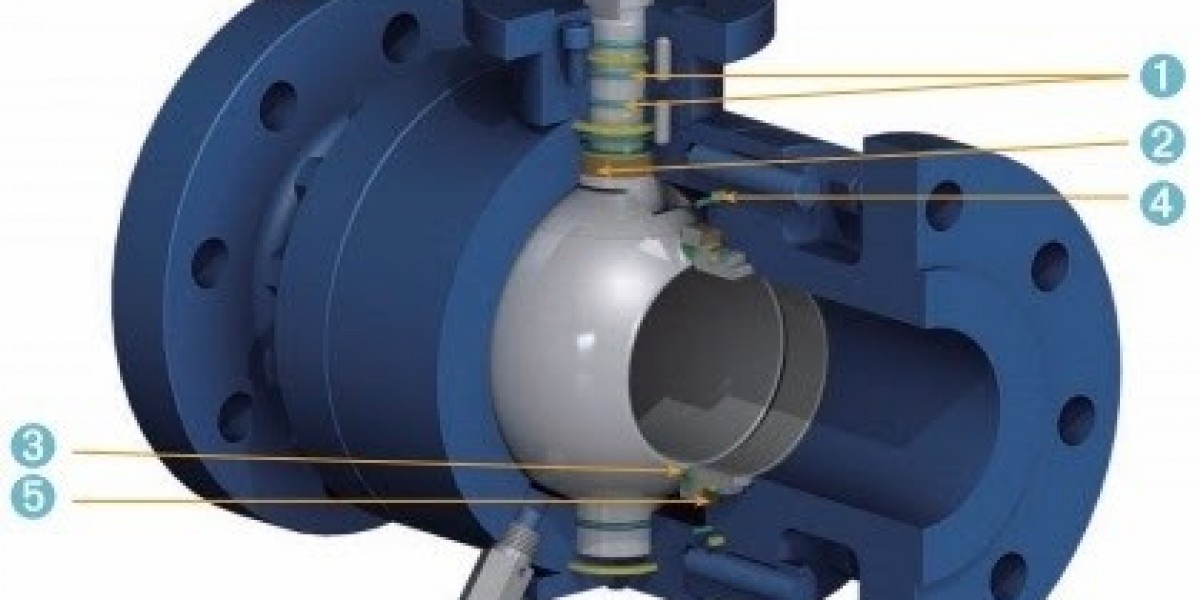

Across industries where high pressure and corrosive media define daily operations, Naishi Trunnion Mounted Ball Valve Factory stands as a symbol of engineering protection. Its design philosophy merges safety principles with advanced material technology, ensuring that every component, from the valve body to the stem seal, performs as a resilient barrier against failure.

Effective maintenance begins with intelligent material choice. In modern valve systems, safety is not achieved solely by inspection or repair—it is engineered from the atomic structure of metals and coatings. Specialized alloys such as stainless steel composites and nickel-chromium blends are chosen for their ability to resist deformation and oxidation under sustained stress. Each material contributes not only to strength but to predictability, allowing operators to anticipate performance over long operational cycles.

The link between maintenance and material science is one of foresight. When the internal composition of a valve can endure abrasion, chemical attack, and thermal fluctuation, maintenance intervals extend naturally. This proactive design minimizes the need for shutdowns, enabling facilities to operate continuously without compromising safety standards. The precision of machining also plays a role; smoother surface finishes reduce friction and prevent microfractures that could lead to premature leakage.

Safety in valve engineering depends on how energy is managed within confined systems. Every trunnion-mounted configuration is built to distribute internal pressure evenly, preventing localized stress points that could cause catastrophic failure. Safety relief mechanisms and reinforced seats further ensure stability, while precision sealing materials prevent gas escape even in fluctuating thermal environments. This structural predictability safeguards workers, equipment, and entire production lines.

Material technology evolves with purpose. Research teams continuously evaluate new composite materials capable of combining hardness with elasticity. By using metallurgical modeling, engineers can forecast how materials behave under extreme temperature or corrosive exposure. The result is a product that requires minimal intervention yet delivers consistent performance, turning maintenance into an act of confidence rather than correction.

Incorporating such innovations represents a deeper commitment to operational security. Industrial safety does not emerge from a single design—it results from the relationship between materials, structure, and human understanding. When every valve is conceived as a safeguard rather than just a component, reliability becomes inherent in every movement of the system.For operators seeking long-term protection through superior engineering, the reliability and innovation of Naishi Trunnion Mounted Ball Valve Factory can be explored at https://www.ncevalve.com/product/fully-welded-ball-valve-1/fully-welded-trunnion-mounted-valve.html