Thermal ceramics are specialized ceramic materials designed to withstand extreme temperatures and provide exceptional thermal insulation. Known also as ultra-high temperature ceramics (UHTCs), these materials maintain their mechanical strength and stability even at temperatures exceeding 2,000 degrees Celsius. Due to their unique properties, including low thermal conductivity, thermal shock resistance, chemical stability, and corrosion resistance, thermal ceramics are increasingly crucial across a wide variety of industrial applications. The global thermal ceramics market is witnessing robust expansion driven by growing industrialization, infrastructure development, and rising demand for energy-efficient and sustainable materials.

Market Size and Growth Prospects

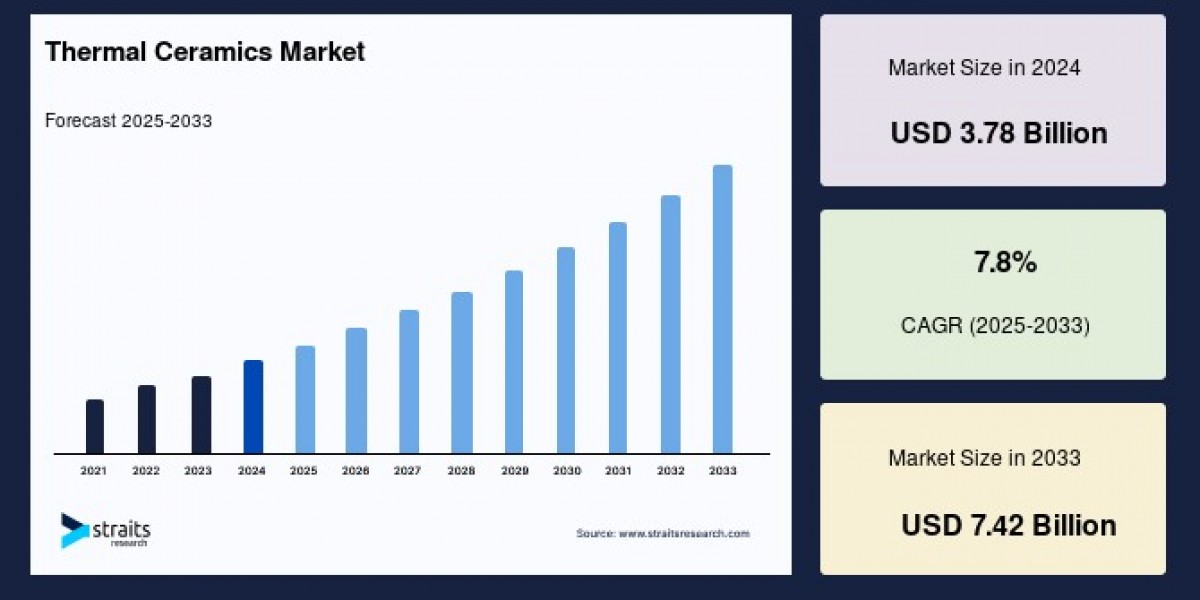

The global thermal ceramics market Size was valued at USD 3.78 billion in 2024 and is projected to reach from USD 4.07 billion in 2025 to USD 7.42 billion by 2033, growing at a CAGR of 7.8% during the forecast period (2025-2033). This growth is fueled by increasing investments in high-temperature insulation solutions across sectors such as metallurgy, petrochemicals, power generation, oil and gas, and construction. Regions such as North America currently dominate the market, with Asia Pacific emerging as the fastest-growing region due to rapid industrialization and infrastructure projects in countries like China, India, Vietnam, and Indonesia.

Key Properties and Advantages

Thermal ceramics demonstrate remarkable properties that make them indispensable for high-temperature industrial processes. They offer exceptional thermal shock resistance, minimizing damage caused by sudden temperature changes. Their thermal insulation capabilities help reduce energy loss and improve process efficiency. Additionally, thermal ceramics have high resistance to chemical attack from alkaline and acidic substances, ensuring durability in harsh environments. The materials also feature good sound absorption and corrosion resistance, supporting their use in diverse sectors.

Applications Driving Demand

Thermal ceramics find extensive applications in many industries. In metallurgy and mining, they are used for hot-face lining in furnaces and kilns, secondary insulation for reheating furnaces, and protection of equipment exposed to extreme temperatures. The oil and gas industry employs thermal ceramics in boilers, heating centers, reactors, crackers, and burner insulation. The energy sector benefits from their use in solar panels combined with photovoltaic cells for enhanced solar power generation efficiency by reducing heat loss.

The construction sector, especially in the Asia-Pacific region, drives demand through extensive use in infrastructures such as dams, bridges, tunnels, rails, and electrical grids. Thermal ceramics contribute to more energy-efficient buildings and infrastructure, aligning with growing sustainability trends.

Product Segments

Ceramic fibers and insulation bricks constitute the primary product types in the thermal ceramics market. Ceramic fibers dominate the market share due to their lightweight nature, flexibility, and excellent thermal insulation properties. These fibers are widely used in fire protection systems, aerospace, automotive, energy, and chemical industries because they provide outstanding resistance to thermal shock and low heat storage.

Insulation bricks, made from lightweight, low-density refractory materials, hold the second-largest market share. They provide superior thermal shock resistance and structural integrity, making them ideal for use in metal processing, glass manufacturing, and power generation industries.

Regional Insights

North America leads the market share due to strong growth in the refractory industry and significant government investments in aerospace, defense, and space exploration sectors. The United States represents the largest revenue contributor within this region.

Asia Pacific is the fastest-growing market, expanding due to rising industrial activity, government infrastructure spending, and evolving chemical and petrochemical industries in countries such as China, India, Indonesia, and Thailand. The region's diverse economies and ongoing industrial revolution foster increasing demand for thermal ceramics in multiple end-use sectors.

Market Challenges and Future Outlook

Despite the promising outlook, the thermal ceramics market faces some challenges. One notable concern is the possible carcinogenic effects associated with ceramic fibers, which could restrain market growth. Additionally, environmental concerns over production byproducts and disposal of ceramic materials necessitate sustainable manufacturing practices.

The market also contends with high initial investment costs and fluctuating raw material prices. However, ongoing technological advancements in nanotechnology, composite materials, and eco-friendly bio-soluble fibers present opportunities for improving product performance and sustainability.

Conclusion

The thermal ceramics market is poised for substantial growth driven by increasing demand for high-performance insulation materials across various industries. Their critical role in enhancing energy efficiency, providing chemical stability, and supporting high-temperature applications solidifies their market importance. Infrastructure development, expanding industrialization in Asia Pacific, and rising adoption in emerging industries such as renewable energy and aerospace will continue to propel the market forward in the coming decade. With sustainable innovations and broader application potential, thermal ceramics will retain their position as essential components for industrial efficiency and environmental responsibility.