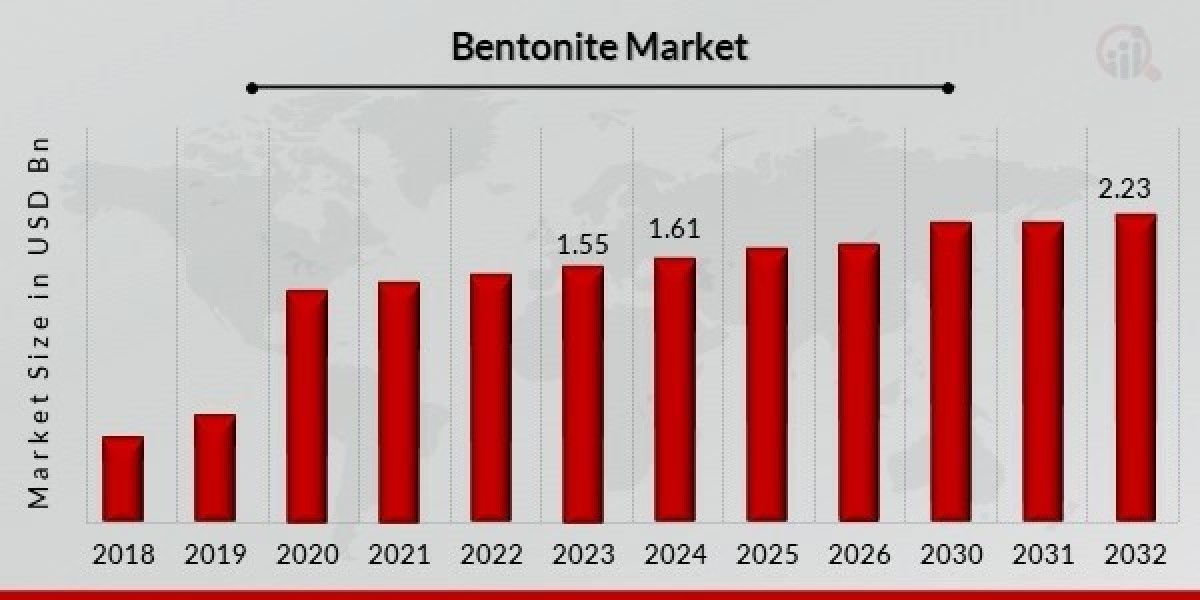

According to the latest research report, the global pin mills market was valued at USD 720.74 million in 2022 and is projected to reach USD 1,240.48 million by 2032, growing at a robust compound annual growth rate (CAGR) of 5.6% during the forecast period. The market expansion is driven by the growing demand for efficient powder processing solutions across industries such as pharmaceuticals, chemicals, food processing, and nutraceuticals.

Pin mills, also known as hammer or disk mills, are widely utilized for size reduction and fine grinding of materials, making them essential equipment for industries requiring uniform particle sizes and consistent product quality. Increasing industrialization and technological advancements in milling equipment are further fueling market growth.

Market Overview

The global pin mills market is witnessing a steady growth trajectory due to the rising need for cost-effective, high-performance milling solutions. Pin mills are highly favored in the pharmaceutical industry for grinding active pharmaceutical ingredients (APIs) and excipients to achieve precise particle sizes. In addition, the food and beverage sector is adopting pin mills to process spices, sugar, and other powdered ingredients efficiently.

The market’s growth is also supported by the increasing focus on automation and advanced material handling systems in manufacturing plants. Modern pin mills come with enhanced safety features, energy-efficient motors, and versatile designs that allow them to handle a wide range of materials, from hard minerals to delicate organic compounds.

Market Segmentation

The global pin mills market can be segmented based on type, application, and end-use industry.

By Type:

Air Classifier Pin Mills: These mills are used for ultra-fine grinding and precise particle classification, making them ideal for high-end pharmaceutical and chemical applications.

Screen Pin Mills: Commonly utilized in the food processing and chemical industries, these mills provide high throughput and consistent particle size distribution.

High-Speed Pin Mills: Designed for rapid processing of materials, these mills are preferred in nutraceutical and bulk chemical manufacturing.

By Application:

Pharmaceuticals: Grinding APIs, excipients, and herbal formulations.

Food and Beverages: Processing sugar, spices, coffee, and powdered food ingredients.

Chemicals: Fine grinding of pigments, fertilizers, polymers, and specialty chemicals.

Others: Including nutraceuticals, feed, and mineral processing applications.

By End-Use Industry:

Pharmaceuticals

Food and Beverage

Chemicals

Nutraceuticals

Other Industrial Applications

??????? ??? ???????? ????????????? ?????? ????:

https://www.polarismarketresearch.com/industry-analysis/pin-mills-market

Regional Analysis

The global pin mills market is geographically segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

North America: The region holds a substantial market share due to the presence of advanced manufacturing facilities, a robust pharmaceutical industry, and early adoption of automated milling solutions.

Europe: The European market is driven by stringent quality standards in food processing and pharmaceutical manufacturing, alongside growing investments in energy-efficient milling technologies.

Asia-Pacific: Expected to witness the highest growth rate during the forecast period, fueled by rapid industrialization, increasing demand for powdered food products, and expansion of the pharmaceutical sector in countries such as China and India.

Latin America: Growth is supported by the rising demand for processed food and beverage products, coupled with government initiatives to modernize industrial infrastructure.

Middle East & Africa: The market is emerging due to the expansion of chemical manufacturing facilities and investments in pharmaceutical production.

Market Opportunity

The global pin mills market presents several lucrative opportunities for industry players. Increasing investments in research and development to design energy-efficient and low-maintenance mills can enhance market penetration. Additionally, the rise of e-commerce and the food supplement industry provides potential for expansion in niche applications such as herbal powders and nutraceutical ingredients.

Furthermore, collaborations and strategic partnerships between pin mill manufacturers and industrial processing companies can accelerate adoption across emerging markets. Companies focusing on providing customized milling solutions with automation and real-time monitoring features are expected to gain a competitive advantage.

Key Companies in the Market

Several global and regional players are actively contributing to the growth of the pin mills market. Key companies include:

Hosokawa Micron Group: Renowned for its high-quality milling solutions and extensive R&D in size reduction technologies.

Fitzpatrick Company: Offers a wide range of pin mills for pharmaceutical, food, and chemical applications.

Siebtechnik GmbH: Focused on air classifier and high-speed pin mills with precision grinding capabilities.

IKA Works Inc.: Specializes in laboratory and industrial milling equipment with innovative automation features.

Bühler Group: Provides versatile milling solutions, particularly in the food processing and nutraceutical sectors.

Other prominent companies include CPM Wolverine Proctor, Netzsch Group, and Pulverisette, which continue to innovate and expand their market presence through strategic collaborations and new product launches.

Industry Trends

Automation and Smart Milling: Integration of IoT-enabled monitoring and control systems is becoming increasingly common, allowing for predictive maintenance and real-time process optimization.

Sustainable Solutions: Manufacturers are focusing on energy-efficient and environmentally friendly milling equipment to reduce operational costs and carbon footprint.

Customization: Growing demand for tailor-made pin mills designed to meet specific industry requirements is driving innovation in mill design and material handling.

Expansion in Emerging Markets: Rapid industrial growth in Asia-Pacific, Latin America, and the Middle East is creating opportunities for market expansion.

Conclusion

The global pin mills market is poised for significant growth, driven by increasing industrialization, rising demand for precise powder processing, and advancements in milling technologies. With a projected market value of USD 1,240.48 million by 2032 and a CAGR of 5.6%, the industry offers ample opportunities for investment and innovation. Key players focusing on technological advancements, strategic partnerships, and market expansion in emerging regions are expected to gain a competitive edge in the coming years.

More Trending Latest Reports By Polaris Market Research:

Molecular Sieve Desiccants Market

Communication Platform As A Service Market

AI-First Product Development Tools Market

Ultrasonic Air Bubble Detectors Market

Distribution Automation Market